About Cost photovoltaic manufacturing plant

Many NREL manufacturing cost analyses use a bottom-up modeling approach. The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers.

Since 2010, NREL has been conducting bottom-up manufacturing cost analysis for certain technologies—with new technologies added periodically—to provide insights into the factors that drive PV cost reductions over time. NREL also creates roadmaps.

Photovoltaic (PV) Module Technologies: 2020 Benchmark Costs and Technology Evolution Framework Results, NREL Technical Report.

Watch these videos to learn about NREL's techno-economic analysis (TEA) approach and cost modeling for PV technologies. They're part of.NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and solar-coupled energy storage technologies. These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride, copper indium gallium diselenide, perovskite, and III-V solar .

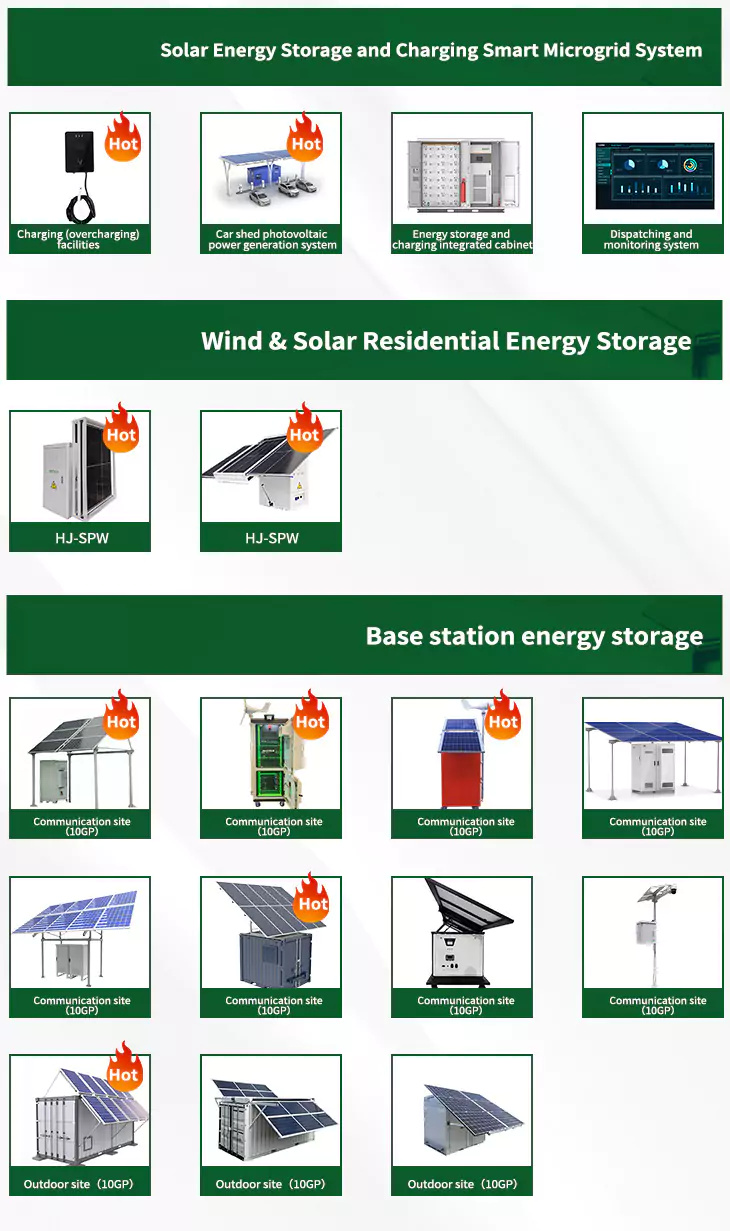

As the photovoltaic (PV) industry continues to evolve, advancements in Cost photovoltaic manufacturing plant have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Cost photovoltaic manufacturing plant for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Cost photovoltaic manufacturing plant featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Solar photovoltaic power plant cost in india

- Solar panel manufacturing plant cost

- How much does it cost to build photovoltaic plant

- Us solar photovoltaic system cost benchmark q1 2018

- Cost of 10 mw solar power plant

- Photovoltaic cell install cost for a farm

- Cost 1 mw solar power plant

- Photovoltaic cost comparison

- Solar power plant setup cost in andhra pradesh

- 5kw solar power plant cost

- 3kw solar power plant cost in india

- 1 mw solar power plant cost 2016 in india