About Defect selective etching of gaasyp1 y photovoltaic materials

Rapid and accurate threading dislocation density (TDD) characterization of direct-gap GaAsyP1−y photovoltaic materials using molten KOH defect selective etching (DSE) is demonstrated. TDDs measured.

••Accurate TDD quantification is important for metamorphic.

The integration of a highly efficient GaAsyP1−y solar cell on Si has been an attractive concept to surpass the theoretical limits of a single junction Si device for years [1], [2], [3].

All samples and solar cells were grown by molecular beam epitaxy and fabricated as previously reported [8], [16], [18], [40]. After growth, the compositions of buffer and device laye.

3.1. Molten KOH GaAsyP1−y bulk etch ratesMolten KOH forms etch pits in GaAsyP1−y with pronounced asymmetry and faceting, resembling.

Molten KOH DSE is demonstrated as a rapid (5–7 min typical etch time) and accurate method to quantify TDD over large areas (>105 µm2) of direct-bandgap GaAsyP1−.

We gratefully acknowledge funding from the NSF CAREER program (Grant no. DMR-09559616). K.N.Y. was supported by the Singapore Energy Innovation Programme Office for a.

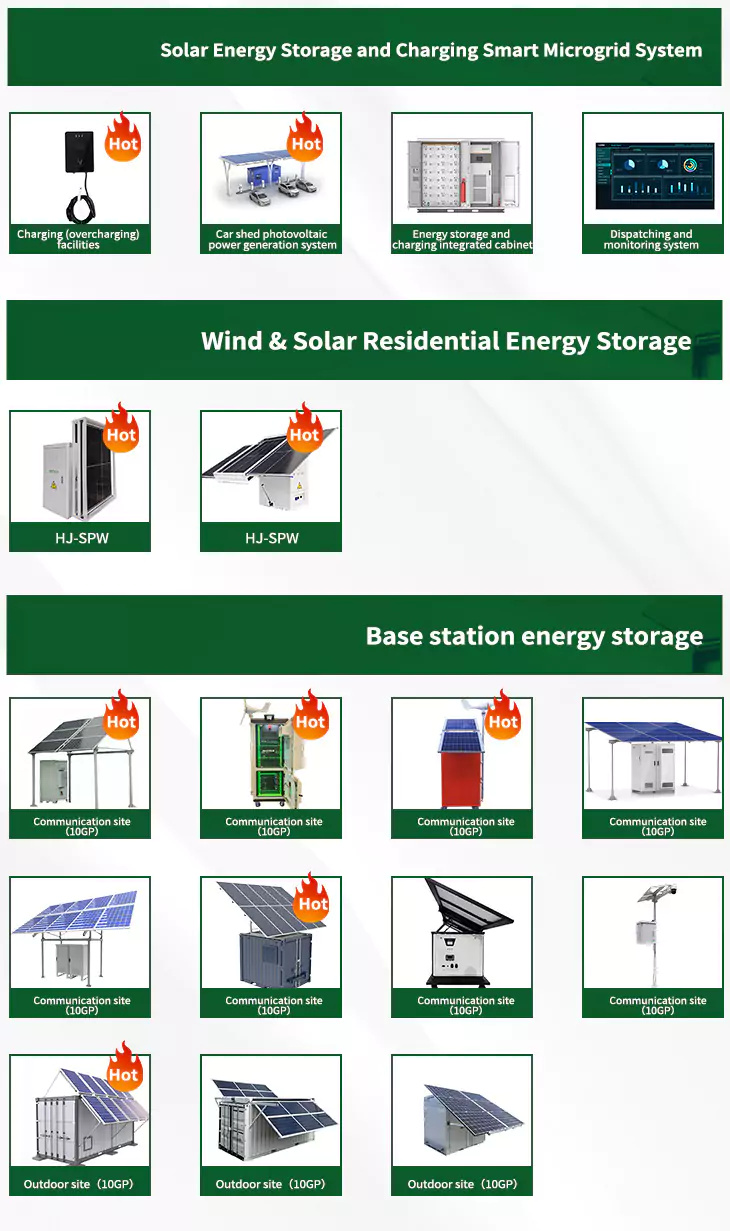

As the photovoltaic (PV) industry continues to evolve, advancements in Defect selective etching of gaasyp1 y photovoltaic materials have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Defect selective etching of gaasyp1 y photovoltaic materials for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Defect selective etching of gaasyp1 y photovoltaic materials featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Plasmonics for improved photovoltaic devices nature materials

- Organic photovoltaic materials

- Photovoltaic materials research

- Photovoltaic tree

- Emmvee photovoltaic bangalore

- Us solar photovoltaic system cost benchmark q1 2018

- German photovoltaic companies

- China photovoltaic solar roof hook

- Deka solar photovoltaic battery

- Grid-tied photovoltaic power systems

- What are photovoltaic solar cells made of

- Easy maintainable mono photovoltaic module 610w in stock