About How to refine lithium for batteries

Although lithium has been known and well-characterized by chemists since the early 1800s, it was only in the middle of the previous century that commercial uses for lithium compounds were identified. Th.

As mentioned before, seawater contains something like 230 billion tonnes of lithium.

To make the most of brine mining while mitigating its shortcomings, direct lithium extraction methods are becoming increasingly popular. In DLE, brine is pumped fro.

As attractive as DLE technology is, at the scale needed to be commercially viable, DLE plants still require a fair amount of energy to run. But in some places, a quirk of geology.

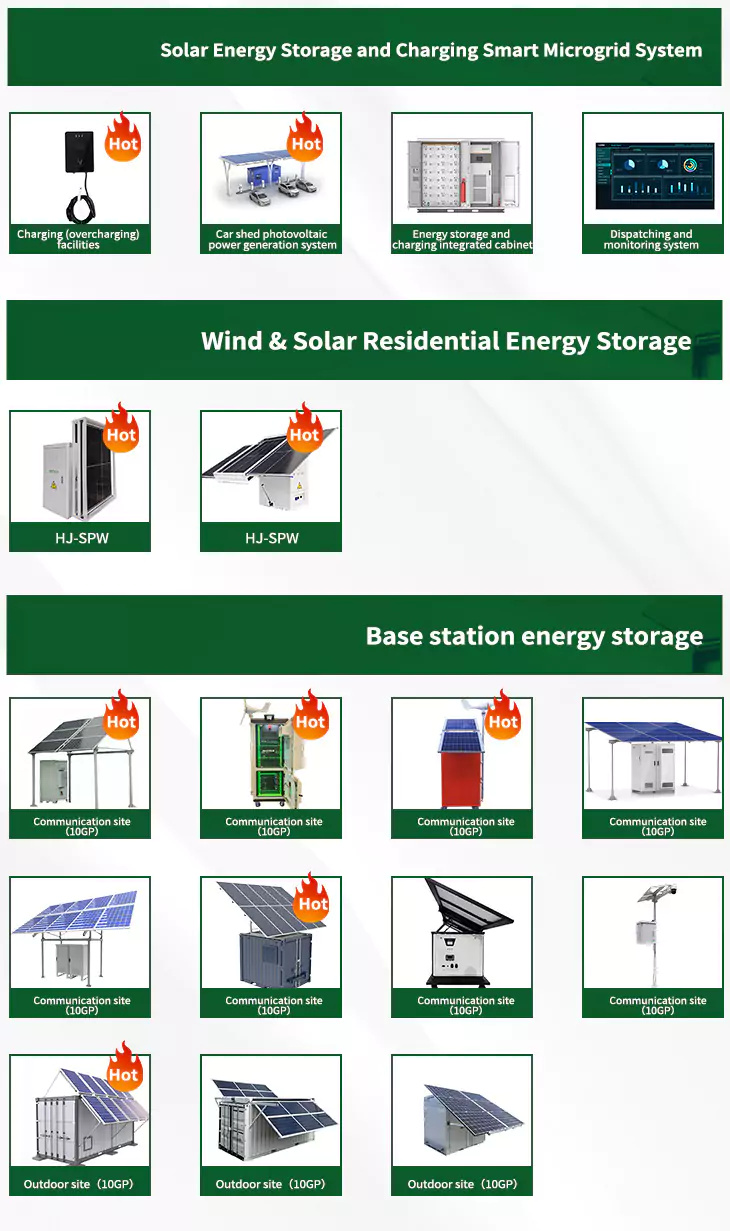

As the photovoltaic (PV) industry continues to evolve, advancements in How to refine lithium for batteries have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient How to refine lithium for batteries for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various How to refine lithium for batteries featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- How to travel with lithium batteries

- How it s made lithium batteries

- How do you make lithium batteries

- How long do lithium batteries last in smoke detectors

- How to mail lithium batteries usps

- How to keep rv lithium batteries warm

- How much are lithium golf cart batteries

- How to travel with lithium ion batteries

- How long do lithium 123 batteries last

- How to get rid of lithium ion batteries

- How bad are lithium ion batteries for the environment

- How to store lithium power tool batteries