About Lithium battery manufacturing equipment

Today, only a handful of companies that specialize in battery cell manufacturing equipment—used for slurry mixing, electrode manufacturing, cell assembly, and cell finishing—are operating in Europe; the majority are in China, Japan, and South Korea (Exhibit 3). However, most of these incumbent battery cell.

EV OEMs and battery cell manufacturing companies will need manufacturing equipment to ramp up production fast and to ensure high.

While equipment manufacturers that already have expertise and capacity for battery manufacturing equipment can use the beneficial funding environment to grow their businesses, others can capture the opportunity by pivoting their competencies. Equipment suppliers.

Equipment companies that are leading in the development of battery competencies exhibit several common characteristics: 1. Eagerness to scout opportunities.The leading equipment companies pay close attention to industry developments and battery manufacturer.

European equipment manufacturers looking to pivot to or expand in the battery cell equipment market can consider four pathways to.

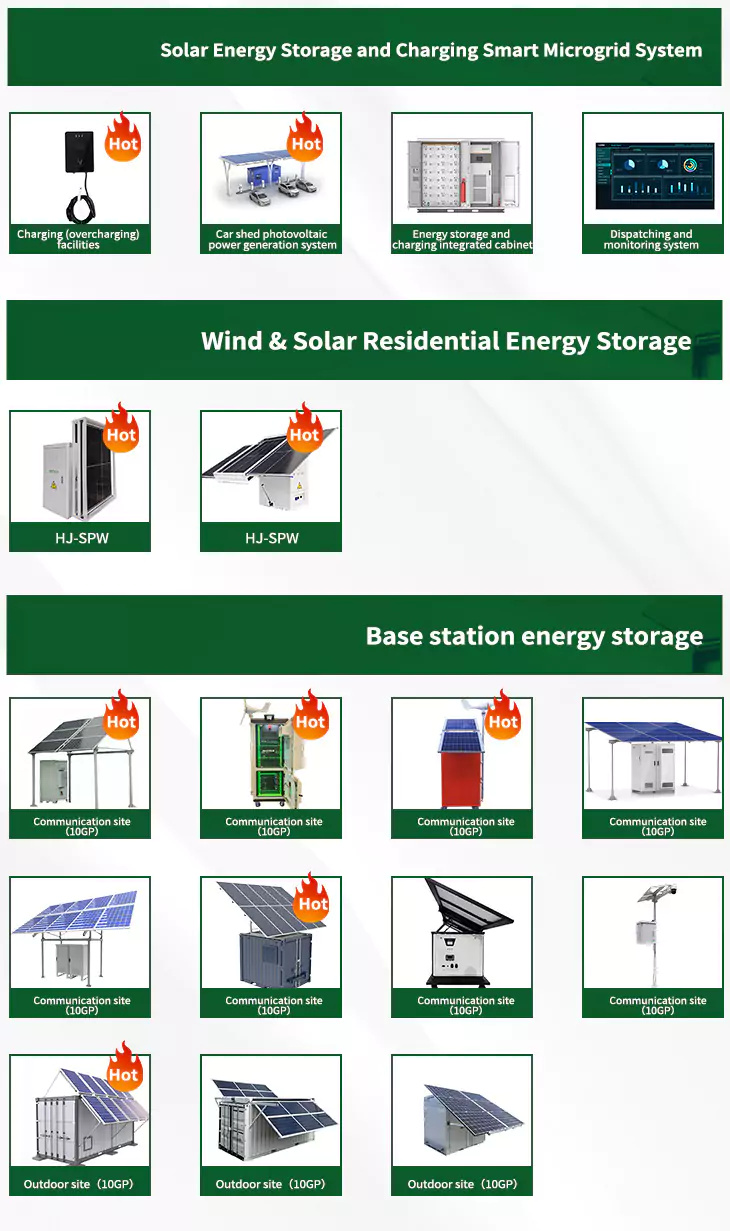

As the photovoltaic (PV) industry continues to evolve, advancements in Lithium battery manufacturing equipment have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Lithium battery manufacturing equipment for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Lithium battery manufacturing equipment featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Lithium ion battery manufacturing process

- Lithium ion battery electrode manufacturing process

- Lithium battery testing equipment

- Lithium battery manufacturing companies

- Duracell 3 volt lithium battery dl1 3n

- Craftsman 19 2 lithium ion battery

- Testing lithium battery with multimeter

- Craftsman lithium ion battery 40 volt

- Lithium battery cr2032 3v

- 72v 32ah lithium battery

- Chins 400ah lithium battery

- Lithium battery will not charge