About Lithium ion battery graphite anode

Graphite is a perfect anode and has dominated the anode materials since the birth of lithium ion batteries, benefiting from its incomparable balance of relatively low cost, abundance, high energy density, powe.

As lithium ion batteries (LIBs) present an unmatchable combination of high energy and power.

Nature carbons have two main forms, namely diamond and graphite, which relates to two hybridization states: sp3 (e.g., diamond) or sp2 (e.g., graphite). For graphite, th.

3.1. Graphite compounds and graphite intercalation compoundsIn graphite intercalation compounds (GICs), the extrinsic substances insert into the graphene l.

Among alkali-metal GICs, lithium GICs are the simplest. The 1 stage LiC6 compound, with a stacking sequence of AαAαAαAα.(roman and Greek letters represent the registry of t.

Graphite will keep being the dominating anode materials for LIBs in the next several decades. Both industrial and academic researchers are pursuing advanced graphite an.

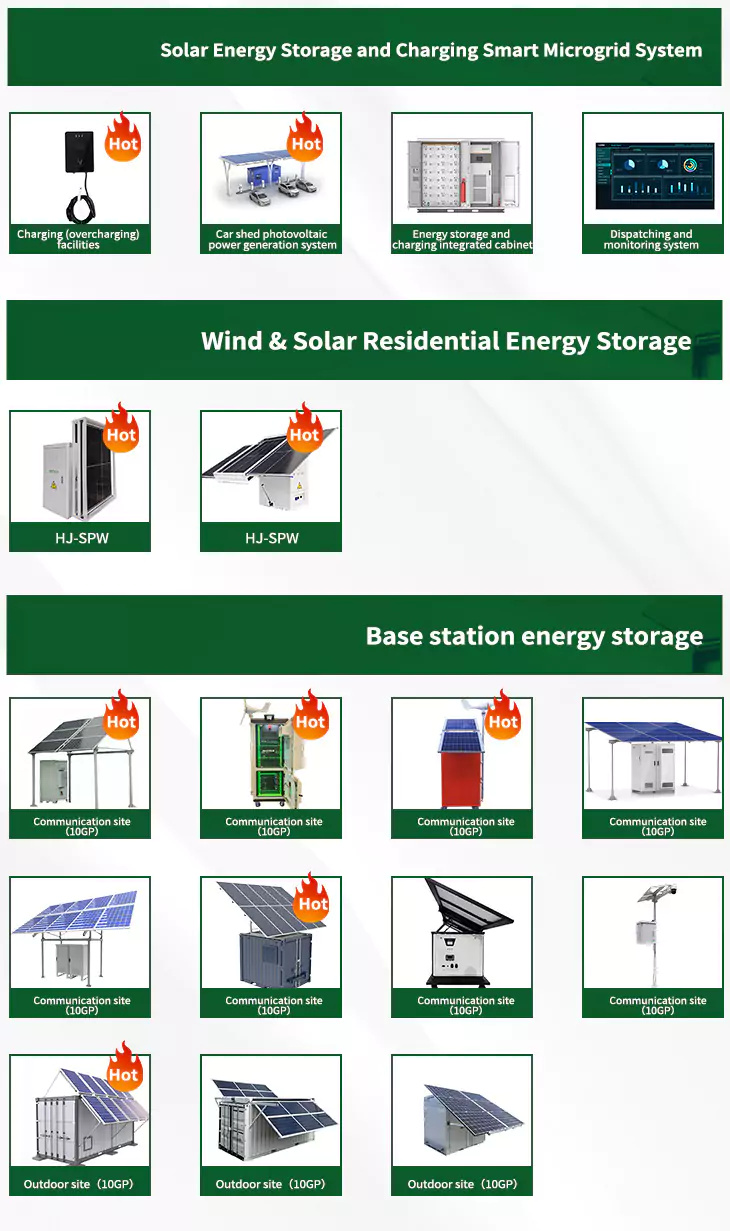

As the photovoltaic (PV) industry continues to evolve, advancements in Lithium ion battery graphite anode have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Lithium ion battery graphite anode for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Lithium ion battery graphite anode featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Craftsman 19 2 lithium ion battery

- Craftsman lithium ion battery 40 volt

- Lithium ion battery winter storage

- Oral b toothbrush with lithium ion battery

- Is there a better battery than lithium ion

- Lithium ion battery hazmat packing group

- 6s lithium ion battery

- Lithium ion battery ac or dc

- Craftsman 18v lithium ion battery

- Lithium ion battery nmc

- How many times can you charge a lithium ion battery

- 28v lithium ion battery