About Pneumatic power system

Pneumatics is a branch of engineering that uses wind or high-pressure air to perform certain operations. A pneumatic system is a connection of various components such as (compressors, intercoolers.

Humans were familiar with pneumatics and the technology behind it since long ago. A.

The air comes into the compressor through an air filter due to the vacuum generated by the blades of the compressor The air is filtered out in the air filter and then goes into the compre.

Pneumatic systems have an infinite number of applications in today’s modern era. Some of the main applications of pneumatic systems are. 1. Automatic production lines. 2. Doors of.

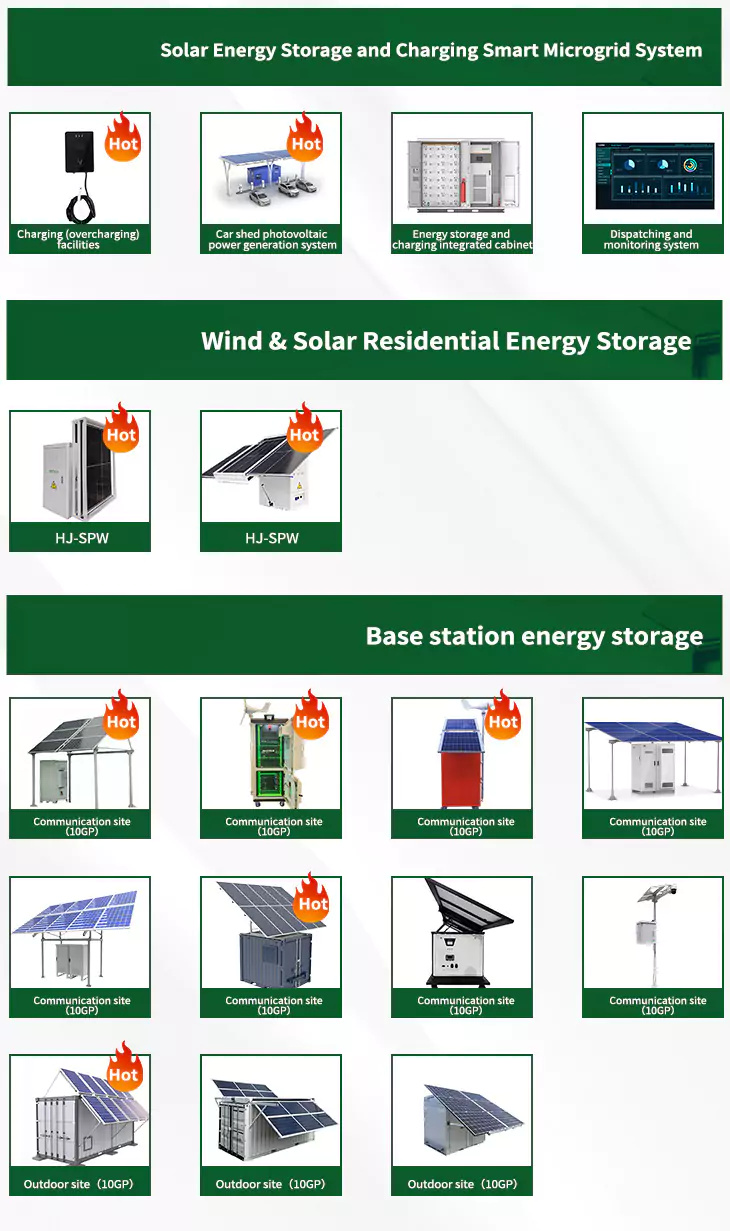

As the photovoltaic (PV) industry continues to evolve, advancements in Pneumatic power system have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Pneumatic power system for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Pneumatic power system featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Hydraulic and pneumatic power systems

- Does solar power produce carbon dioxide

- Check vsa system and power steering

- Liebert ac power system

- 3000 watt solar power inverter

- Electrical power system by cl wadhwa pdf

- Noma backup power system 400

- Cirrus power systems

- Power tool battery recycling near me

- Lost power cord for old western digital 500gb backup drive

- 24vac power adapter transformers system

- Backup power source for sump pump