About Silicon monocrystalline photovoltaic cells

Crystalline silicon (c-Si) photovoltaics has long been considered energy intensive and costly. Over the past decades, spectacular improvements along the manufacturing chain have made c-Si a low-cost s.

Photovoltaics is a major actor of the ongoing energy transition towards a low-carbon-emission.

For high-efficiency PV cells and modules, silicon crystals with low impurity concentration and few crystallographic defects are required. To give an idea, 0.02 ppb of inter.

The indirect bandgap of silicon yields only a moderate absorption and, thus, requires a wafer thickness of 100–200 µm to absorb most of the light with energy above the bandgap. F.

Most silicon solar cells until 2020 were based on p-type boron-doped wafers, with the p–n junction usually obtained by phosphorus diffusion, and, until 2016, they were mostl.

In PERC and PERT solar cells, metal contacts silicon locally on both sides. This leads to significant recombination, limiting the open-circuit voltages. This problem of ‘classic met.

Monocrystalline silicon is also used for high-performance(PV) devices. Since there are less stringent demands on structural imperfections compared to microelectronics applications, lower-quality solar-grade silicon (Sog-Si) is often used for solar cells. Despite this, the monocrystalline-silicon photovoltaic industry has benefitted greatly from the development of faster mo. Monocrystalline cells were first developed in 1955 [1]. They conduct and convert the sun’s energy to produce electricity. When sunlight hits the silicon semiconductor, enough energy is absorbed from the light to knock electrons loose, allowing them to flow freely.

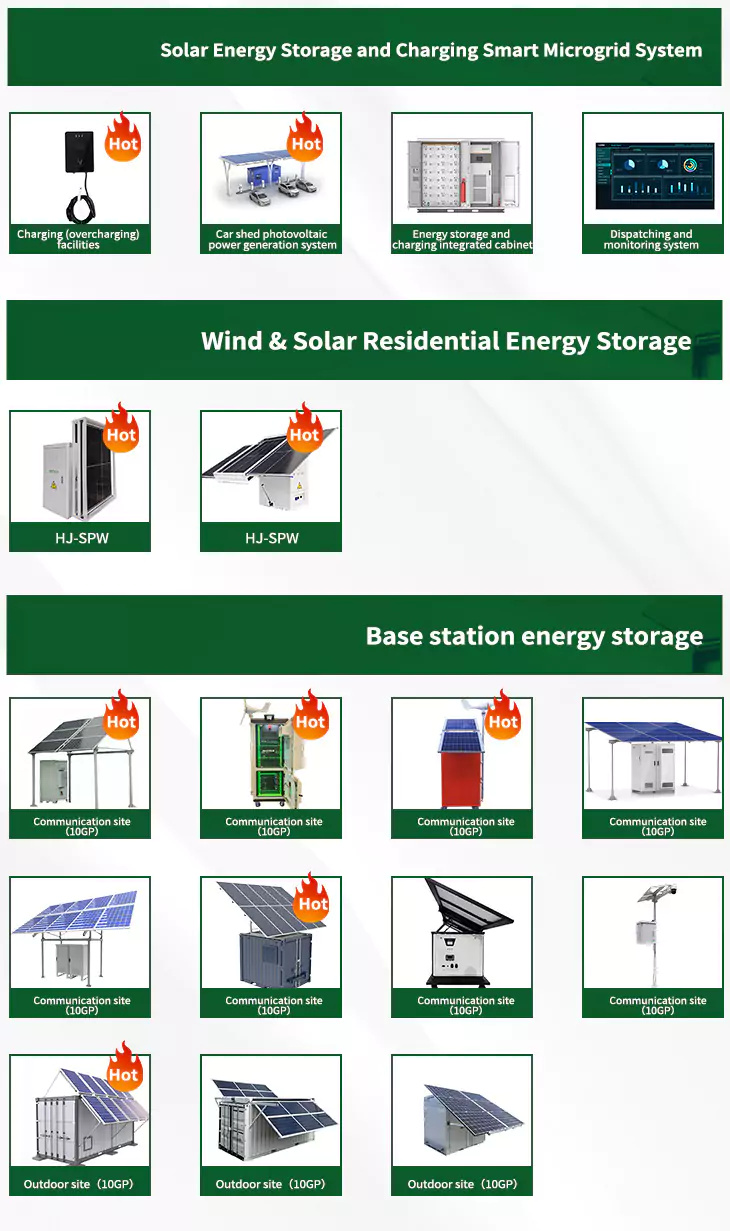

As the photovoltaic (PV) industry continues to evolve, advancements in Silicon monocrystalline photovoltaic cells have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient Silicon monocrystalline photovoltaic cells for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various Silicon monocrystalline photovoltaic cells featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Related Contents

- Photovoltaic cells require silicon

- Crystalline silicon photovoltaic cells adcvd from indonesia

- Monocrystalline solar cells vs photovoltaic

- Dvantages of thin-film amorphous silicon photovoltaic panels

- Amorphous silicon thin film solar cells for flexible photovoltaics

- Solar silicon photovoltaic market

- What are photovoltaic solar cells made of

- Photovoltaic cells uv vis spectroscopy

- How do photovoltaic cells work animation

- Giga factory for photovoltaic cells

- High efficiency photovoltaic cells

- Solar energy conversion process in photovoltaic cells